At Measom Freer, we put the customer first. We believe you should be able to source the exact plastic product you require – without having to make sacrifices. That means not settling for a colour that doesn’t suit, a capacity that isn’t quite right or a plastic that fails to meet your commitment to the environment. For both our own and our custom moulding we only work with responsibly sourced recyclable and recycled thermoplastics.

We are one of Leicester's oldest Injection Moulders and Extrusion Blow Moulders. Established in 1937 and now on our 4th generation as a family run business we know we can help you realise your projects.

As well as manufacturing and stocking recycled and recyclable plastic bottles and packaging we also specialise in the design, development and manufacture of bespoke products. Attention to detail and a personal touch are paramount to the service offered and we thrive on producing a solution for even the most demanding packaging challenge.

What is custom moulding?

Our custom moulding service involves designing and producing a plastic product exactly to your specification and requirements.

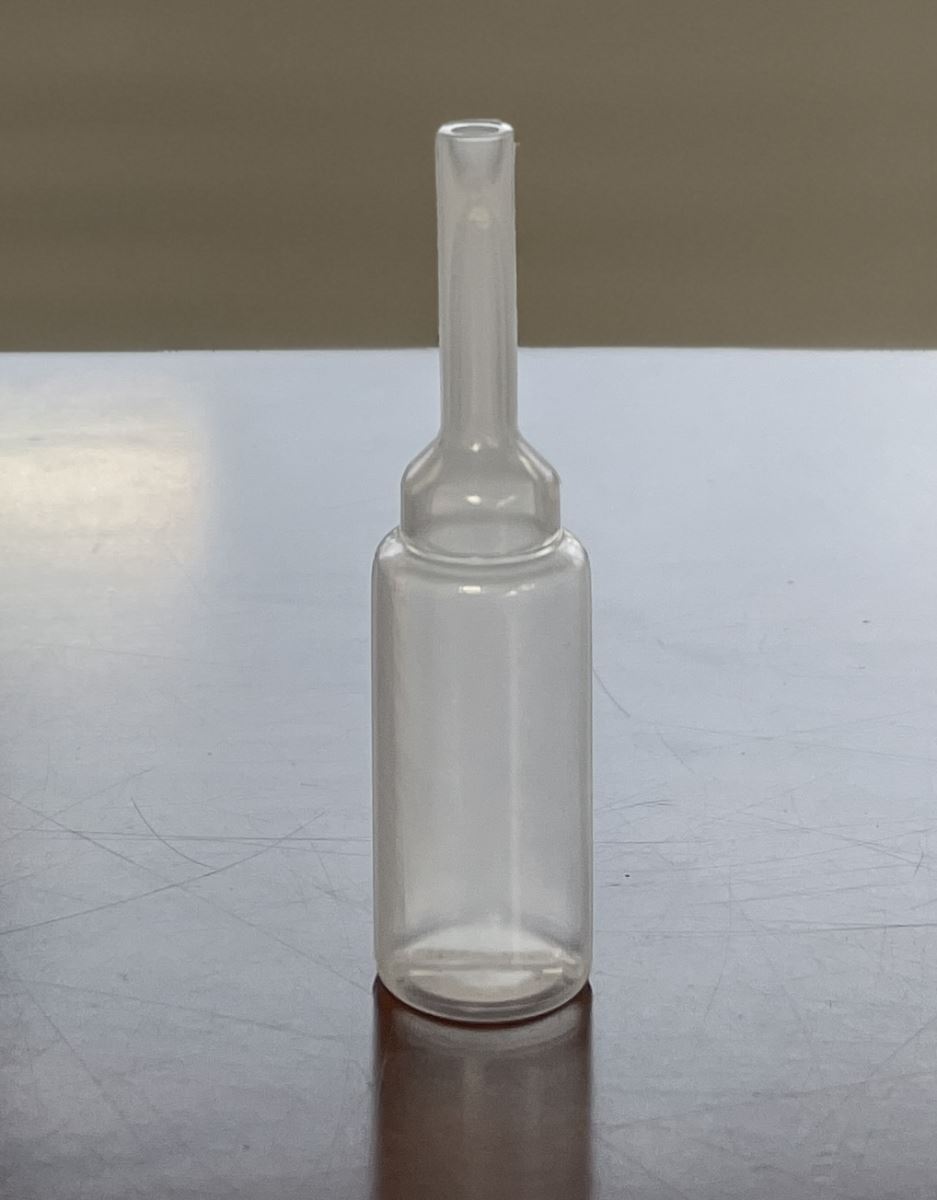

We can manufacture bespoke packaging, flexible polythene bellows, pycnometer bottles & containers, technical mouldings, parts, components, bottles, jars, boxes, caps, plugs, measures, spatulas, scoops, spoons, tubes, fasteners and more.

Types of Custom Moulding we offer:

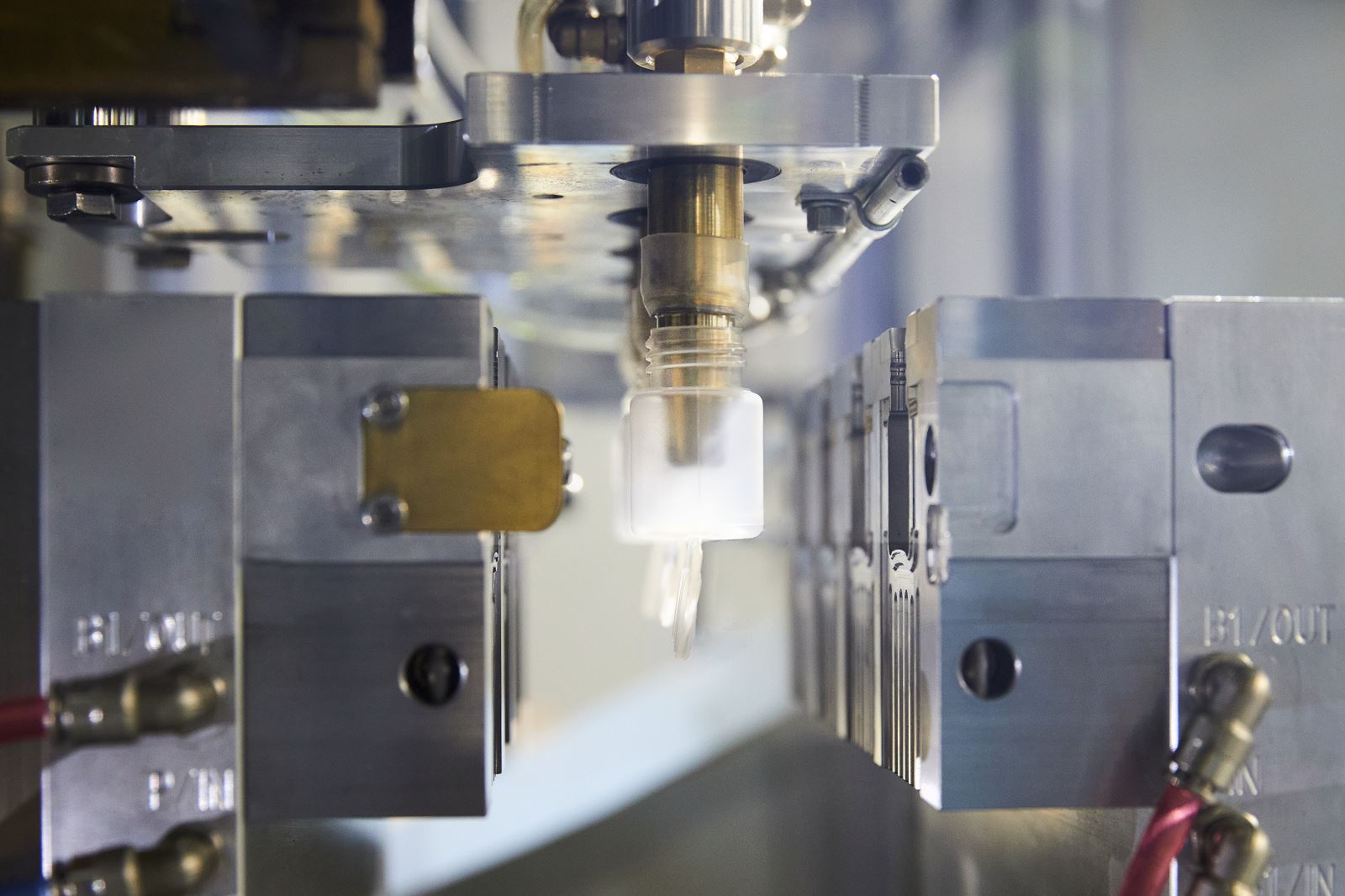

- Blow Moulding - Plastic blow moulding is a manufacturing process for forming hollow plastic parts like bottles and containers. Here at Measom Freer we use Extrusion Blow Moulding; a hot tube of plastic material, called a parison, is forced through an extruder and captured in a water-cooled mould. Once the mould is closed, the parison is cut, the mould moved over to a blowing station, then air is blown into the top or the neck of the container pushing the plastic out to meet the cavity within the mould. When the hot plastic material is blown up and touches the walls of the mould the material cools rapidly and the container maintains its rigid shape. One of the key benefits of blow moulding is that it can be used to manufacture complex shapes – something that can be of tremendous value for such things as product branding and identity We can utilise this process for capacities up to 2 litres and it is ideal for plastic bottles, containers and unusual items like plastic bellows. We can use most thermoplastics for blow moulding, including PVC, HDPE, rHDPE, LDPE, PETG, rPETG, Bioplastics, rPP and PP, with up to 2-litre capacity.

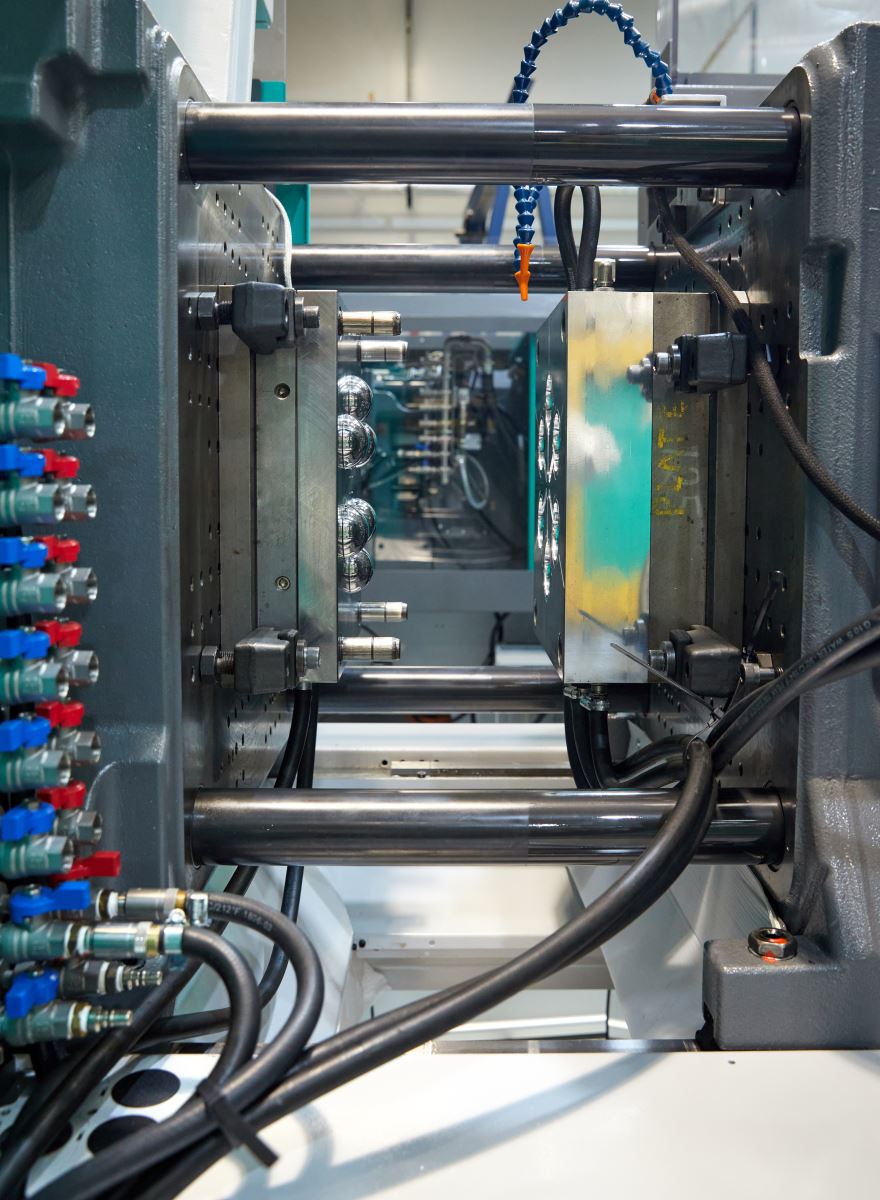

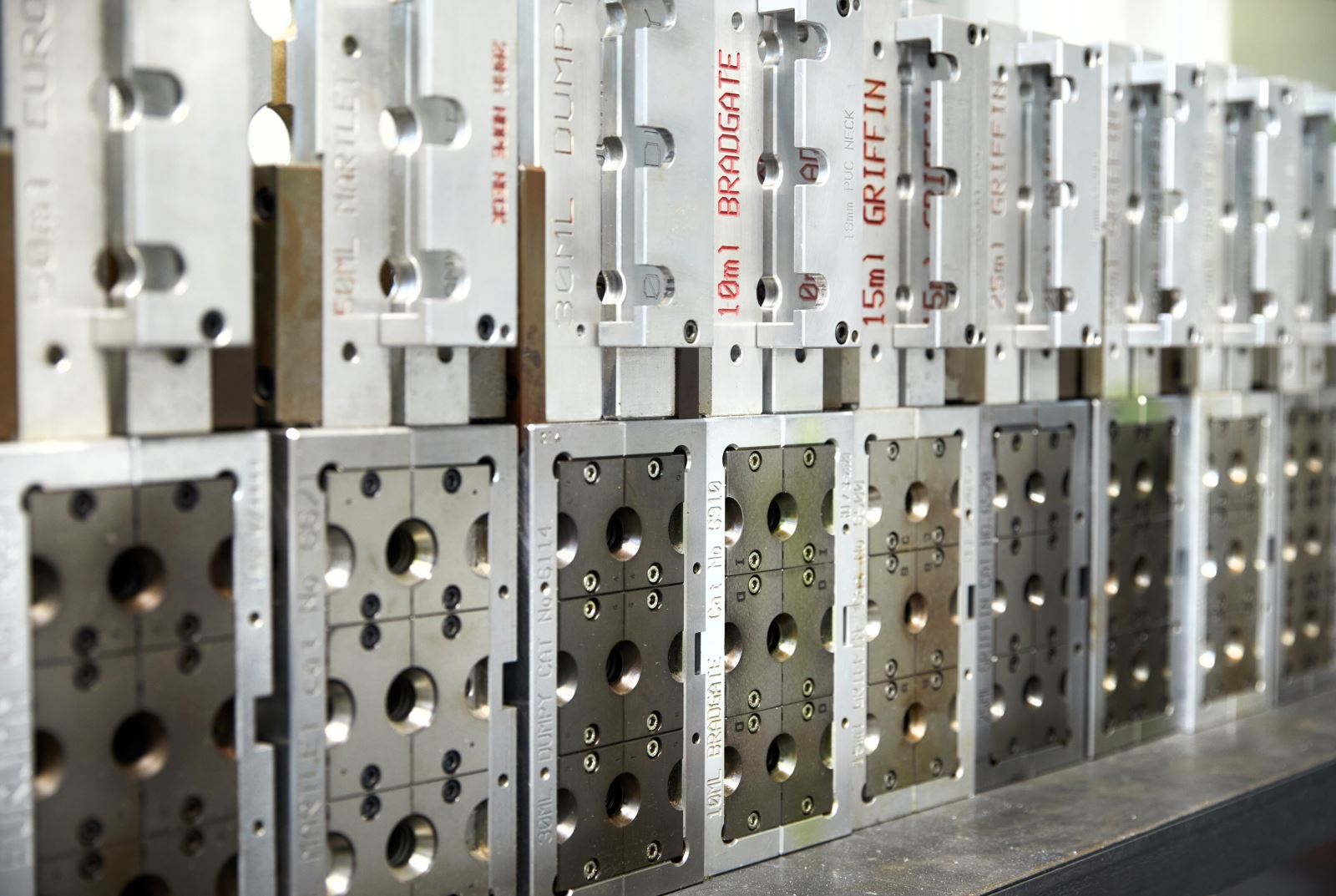

- Injection Moulding - Plastic injection moulding is the process of melting plastic pellets (thermoplastic polymers) that once molten, are injected at pressure into a mould cavity, which fills and solidifies to produce solid parts like caps,measuring scoops, components and parts. This process can be used with most recyclable thermoplastic materials, and we can mould up to a shot weight of approximately 350g. Injection moulding is able to produce large volumes of quality parts at a high rate of speed and with accuracy.

How we work

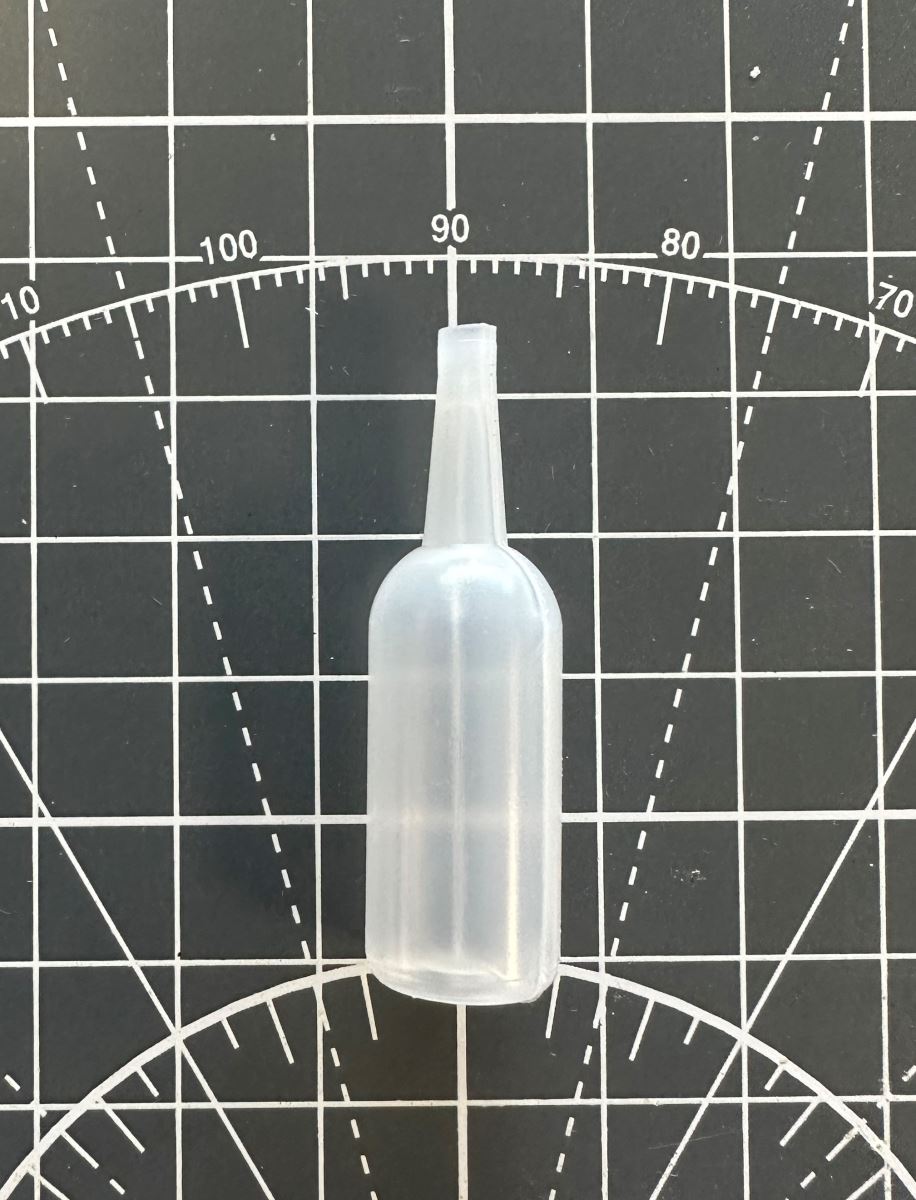

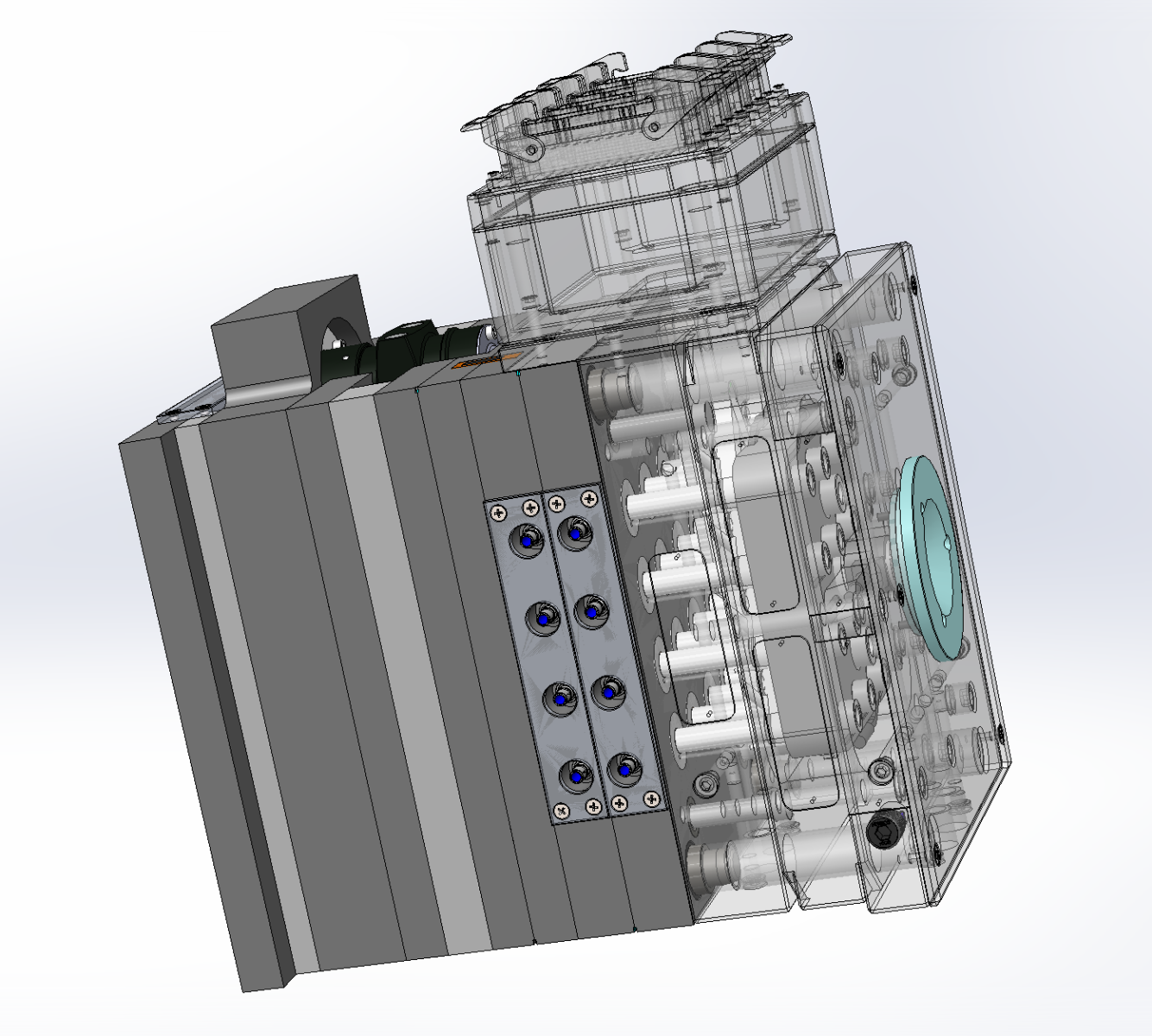

Our Design Department and In-House Toolroom are equipped with the latest CAD/CAM facilities for component design, 3D visualisation and modeling. We can manufacture prototypes of your required designs for you to evaluate before full production - so you can be confident the final product will look exactly as you’re expecting and function as required.

Within the Design Department and Toolroom we continually invest in cutting edge technology (pardon the pun!), modern equipment and developments that ensure we manufacture tooling to exacting British Standards for your products.

We use Solidworks for our design which is a hugely flexible system which can generate 3D models for the customer to view with a downloadable viewer (eDrawings). This helps the customer see their designs and helps the design process go smoothly. We can accept most file formats, including your own STEP files to work from.

Need a competitive price? We always strive to offer fair pricing and cost-effective services, which is why we have 24-hour production cycles to ensure maximum output at economical prices.

Find out more about our Custom Moulding Services

Our bespoke services mean we can design and create high quality, recyclable & recycled plastic bottles, containers and injection moulded parts to fit seamlessly with your business. And, of course, we promise strict confidentiality at all stages, to protect your designs and brand.

Our reputation in the business is a testament to our experience and exceptional customer service, so why not put us to the test? Get in touch to find out more or to discuss your requirements in more detail. Our skilled team can help you to identify the ideal custom mould solution and will assist you right the way through to the overall finished design and look.

Call us on +44 (0)116 288 1588 or complete our contact form and we’ll get back to you as quickly as we can.

Call us on +44 (0)116 288 1588 or complete our contact form and we’ll get back to you as quickly as we can.

Why stop there?

If you’re looking for ways to maximise your branding, then why stop at our custom moulding service? After perfecting the design and shape of your bottle, complete the look with our bespoke printing and labelling services. With the help of our talented in-house team, you can ensure your bottle design is finished to perfection with the inclusion of logos and text in either one or multiple colours - find out more now.